|

|

|

Main Uses:

|

|

Cladding, Decking, Louvre Blades and Brise Soleil. Saunas and Garden Furniture, Internal Cladding including Bathrooms & Kitchens.

|

Thermowood comes in a range of sizes and is an ideal timber for use in exposed areas such as external wall cladding.

|

|

What is Thermowood ®? Thermowood is produced by treating softwood in special chamber kilns at high temperatures. The cellular structure changes during the heat treatment and as a result Thermowood is more stable than untreated wood in changeable climatic conditions.

|

Thermowood's high resistance to moisture or decay causing fungi, makes it an excellent material for use as a cladding.

|

|

|

|

|

|

|

|

|

Environmental Benefits:

|

|

Thermowood ® production process uses heat vapour and steam only and NO CHEMICALS that will have detrimental effect on the environment. No foreign substances are added to the wood during the treatment process, ensuring that any cutting waste can be burnt, recycled and composted or disposed of safely.

|

|

|

|

|

Surface Treatment:

|

|

Thermowood is a superior base for receiving surface treatment than normal softwood because there is much less movement in Thermowood.

|

|

However it can be left untreated to turn grey in colour if a more natural effect is required.

|

|

Modern styles of architecture often call for highly durable, natural, sustainable, environment friendly, materials - but sometimes the price of traditional timber species (Cedar / Oak) is too high.

|

|

Thermowood provides a cost effective solution.

|

|

|

|

|

The Timber

The timber used to produce Thermowood ® is mainly softwood grown in Scandinavian forests which are fully certified under the Programme for the Endorsement of Forest Certification (PEFC). As such you can be sure that Thermowood products are sourced from well managed and sustainable forests. The heat treatment process requires no chemical additives. The improved performance is achieved simply by the controlled application of heat and steam.

Drying

Thermowood is produced by heat treating to 212 degrees for Thermowood 'D' for durability and stability, 190 degrees for Thermowood 'S' for stability.

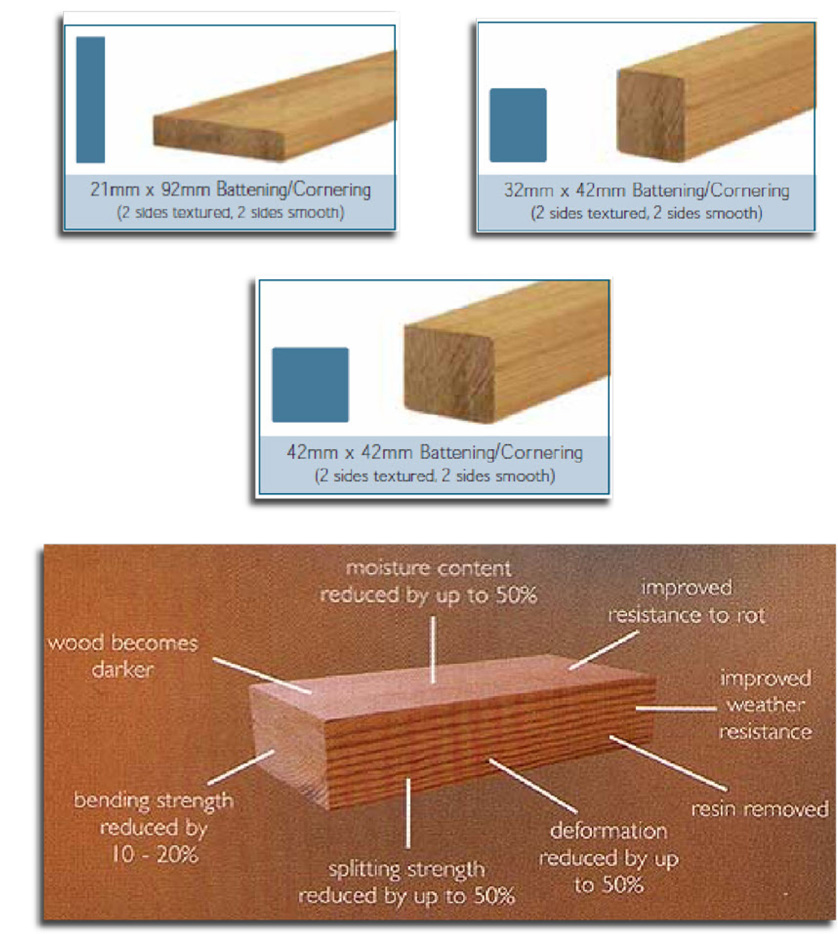

During the heat treatment, chemical and structural changes occur within the timber which alter and improve some of its basic characteristics.

The temperature removes some of the natural additives which creates a better performance.

Stability

Thermowood is more stable than untreated softwood. The changes occur within the timber during heat treatment which makes it absorb less moisture. This restriction of moisture limits potential for swelling, shrinkage or distortion of Thermowood cladding boards.

Work Qualities

Thermowood can be used in many areas including interior as well as exterior cladding. Examples of end uses are louvres and Brise Soleil, floors and indoor ceilings, mouldings and sections, facades, garden furniture, playground equipment, noise screening, sauna panelling, fences and terraces. It is an ideal material for use in exposed areas such as external wall cladding.

Treatability

Accepts stains / paints being kiln dried and also accepts FR Treatments.

Movement

Thermowood is a material of small movement in service.

Recommended Fixing

Stainless Steel / Non Ferrous Metals, Nail or Screw, Power Nailers should be avoided.

Density

Thermowood density is 350 - 480 kg/m3. When the moisture content is 6%, natural variation will occur between the individual boards.

Colours

The colour of Thermowood is affected by the treatment temperature and the length of time in the process, the higher the temperature the darker the timber. Variance in colour will differ due to the density of the softwood. When exposed to UV light it will turn a silvery grey unless protected by a stain.

|

|

|

Corner and Trim Options Thermowood 'D'

|

|

30 Years Service Life

|

|

|

Sizes are accurate when timber is machined. Timber will move during different climatic changes for which we have no control over whatsoever. We reserve the right to amend profile dimensions without notice. Please check current dimensions with our sales office if you are matching up profiles that have been supplied in the past. |

|