| |

THERMOWOOD® DECKING IS A RICH GOLDEN COLOUR SIMILAR TO THAT OF HARDWOOD WHICH IF LEFT UNTREATED WILL FADE TO A SILVERY GREY ONCE EXPOSED TO THE ELEMENTS.

|

THERMOWOOD® DECKING IS HEAT TREATED TO CLASS THERMO-D AT TEMPERATURES OF 212°c MAKING IT SUITABLE FOR EXTERNAL USE.

THERE ARE THREE MAIN PHASES TO THE TREATMENT PROCESS:

|

|

1. |

USING HEAT AND STEAM THE TEMPERATURE IN THE KILN IS RAISED TO 100°:c. THEREAFTER THE TEMPERATURE IS RAISED TO 130°c ALLOWING THE DRYING PROCESS TO TAKE PLACE AND THE MOISTURE CONTENT DECREASES TO ALMOST ZERO.

|

|

2. |

ONCE ThE DRYING HAS TAKEN PLACE THE KILN TEMPERATURE IS RAISED TO 212°c AND THIS CONSTANT TEMPERATURE REMAINS FOR 2-3 HOURS DEPENDING ON THE END USE APPLICATION.

|

|

3. |

FINALLY THE TEMPERATURE IS LOWERED WITH WATER SPRAY SYTEMS. WHEN 80-90°c IS REACHED RE-MOISTURISING TAKES PLACE ALLOWING THE WOOD MOISTURE CONTENT TO RISE TO A USEABLE LEVEL OF 4-7%.

|

- GENERAL MAINTENANCE INCLUDING REGULAR CLEANING WITH A MILD DETERGENT WILL EXTEND THE LIFE OF THERMOWOOD® DECKING.

- TO MAINTAIN THE RICH COLOUR, TREAT THE THERMOWOOD® ANNUALLY WITh A DECK OIL OR STANDARD PRESERVATIVE DECK TREATMENT.

|

- THERMOWOOD DECK BOARDS CAN BE FIXED WITH STANDARD DECK SCREWS OR CLIPS

- IF CUT, SAWN ENDS SHOULD BE RE-TREATED WITH A SUITABLE TIMBER PRESERVATIVE

- SUPPORTS SHOULD BE SET AT A MAXIMUM OF 400mm CENTRES. A SLIGHT FALL SHOULD BE INCORPORATED INTO THE DESIGN TO HELP IMPROVE DRAINAGE

|

|

|

|

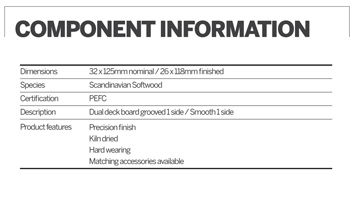

Nominal

(mm) |

Finished

Dimensions (mm) |

Length

(m) |

|

|

32 x 125 |

26 x 118 |

3/3.3/3.6/3.9/4.2/4.5/4.8/5.1/5.7 |

|

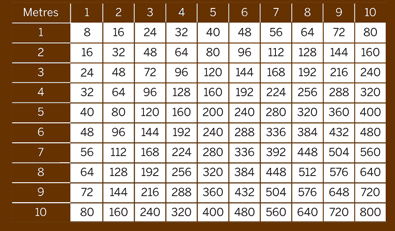

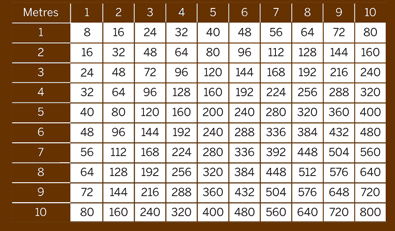

USING 125mm WIDTH NOMINAL SIZE DECK BOARDS

|

ACCORDING TO EN13501 (SBI TEST) THERMOWOOD® IS IN A REACTION TO FIRE CLASS D. IT IS POSSIBLE TO TREAT FURTHER WITH FIRE PROTECTIVE TREATMENTS IN ORDER TO ACHIEVE FIRE CLASS RATING 1 SPREAD OF FLAME.

|

- THE PRODUCT HAS A MOISTURE CONTENT OF 5-7% (50%RH) WHEN PACKED IN PRODUCTION.

- THIS LEVEL WILL CHANGE ACCORDING TO ATMOSPHERIC CONDITIONS.

|

|